So, I’ve been tinkering with this coaxial movement thing for a while now, and I thought I’d share my little journey with you all. It’s been a wild ride, let me tell you.

It all started when I stumbled upon some old article about a guy named George Daniels. Apparently, this dude was a watchmaking legend, and back in the 70s, he cooked up this new way for watch movements to work called the “coaxial escapement.” I was intrigued, I mean, who wouldn’t be? A new way to make watches tick? Sign me up!

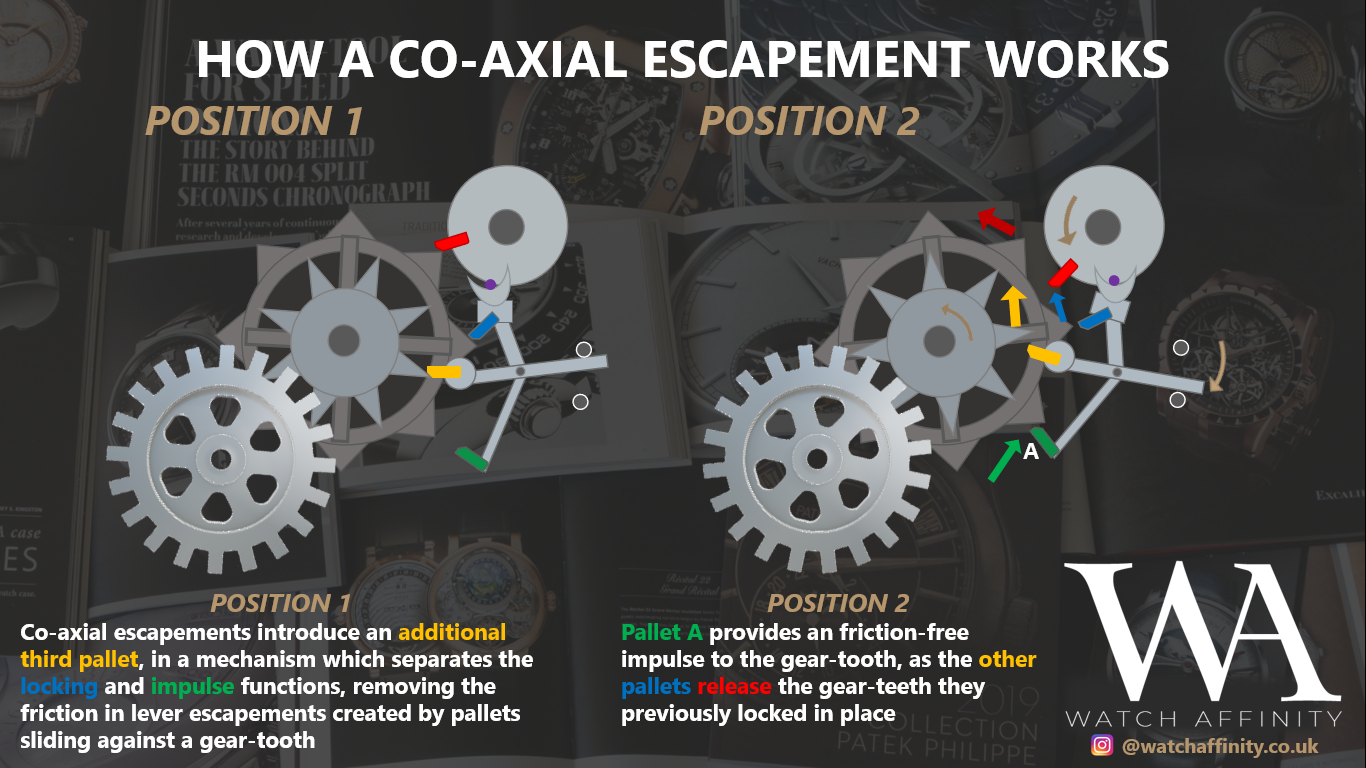

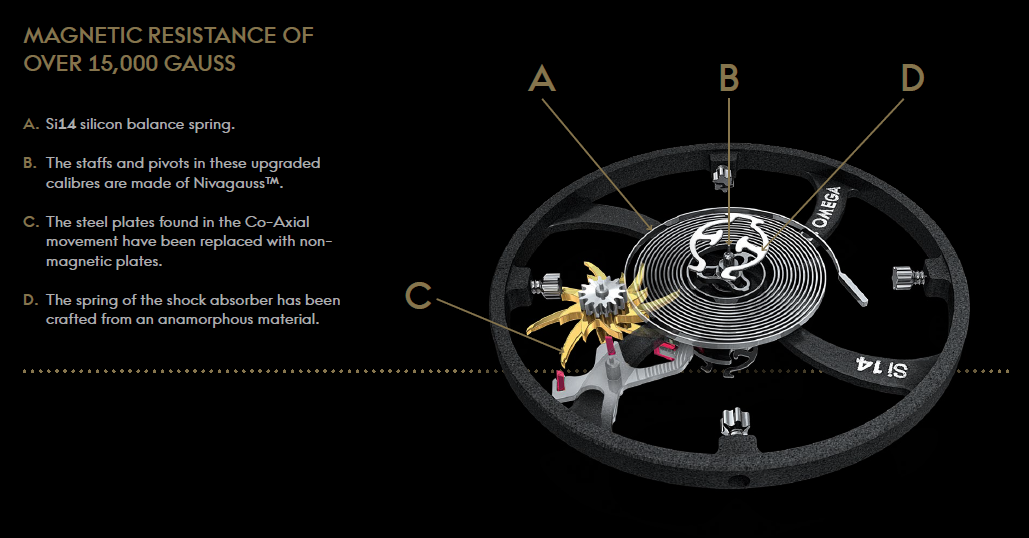

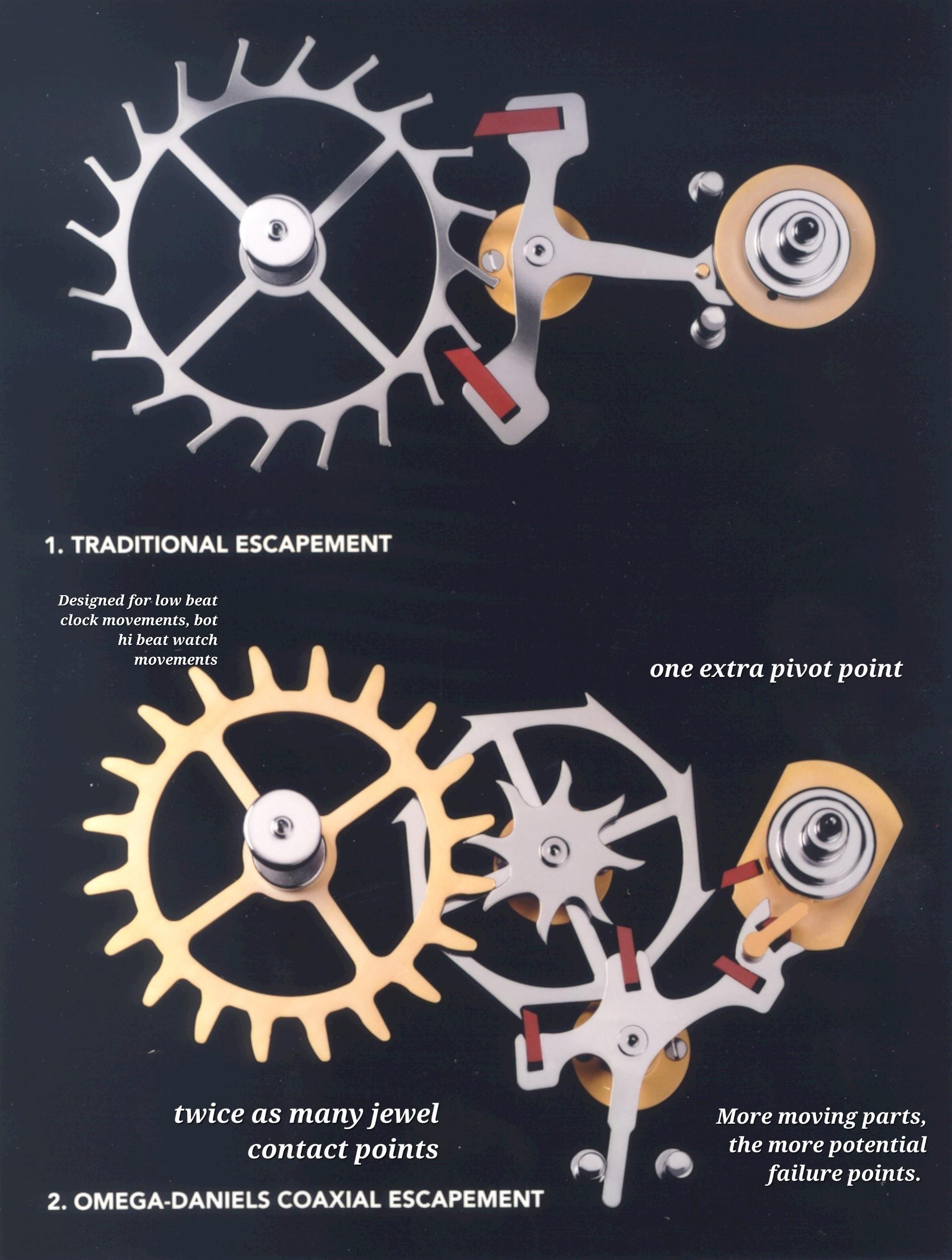

I started digging deeper, trying to find out how this coaxial thing actually worked. From what I gathered, the whole idea is to make the watch movement more efficient. See, in a regular watch, there are these parts that slide against each other, and that creates friction. This coaxial thing, though, it’s designed to reduce that sliding friction by using some kind of “pushing” action instead. Less friction means the watch runs smoother and in theory should be more accurate over time.

I spent days, maybe weeks, just reading about it and trying to wrap my head around the whole concept. The regular movement that almost all watches had used for years was already pretty complicated. This coaxial thing though, it was next-level. It involved adding extra wheels and changing the shape of parts, and just generally making the whole thing way more complex.

After a while, I decided I had to try building one myself. I mean, how hard could it be, right? (Famous last words, I know.) I started sketching out designs, trying to figure out how all the pieces would fit together. I’d spend hours staring at these tiny diagrams, trying to visualize how the movement would work.

Getting my hands dirty was the next step. I ordered a bunch of watch parts online, and when they arrived, it was like Christmas morning. I cleared off my workbench, laid out all the tiny gears and springs, and got to work. I spent many evenings hunched over my workbench, my eyes glued to a magnifying glass, trying to assemble this tiny, intricate mechanism. The parts were so small! Tweezers became my best friends during this time.

There were definitely moments of frustration. Times when I just couldn’t get things to fit together right, or when I accidentally dropped a crucial part and spent the next hour on my hands and knees searching for it. There may have been a few curses thrown around, I’m not gonna lie.

But I kept at it. Slowly but surely, the movement started to take shape. I used an existing watch’s movement as a reference point, carefully modifying it based on the coaxial designs I had found. It was a painstaking process of trial and error.

- First Try: Total failure. Nothing worked. Back to the drawing board.

- Second Try: Got some parts moving, but it was jerky and unreliable.

- Third Try: Closer, but still not quite right. It would run for a few seconds, then stop.

- And many more tries later… I was almost giving up.

Then, after countless attempts, it finally happened. I made some final adjustments, wound up the watch, and held my breath. The movement started ticking. And it kept ticking! It wasn’t perfect, not by a long shot, but it was working. It was a messy, rough, prototype of a coaxial movement, but I had made it with my own two hands.

It was a breakthrough!

I was over the moon! I’d actually managed to build a (somewhat) working coaxial movement. It was a huge accomplishment for me. I felt like I learned a ton during the journey.

So, yeah, that’s my coaxial movement story. It’s been a challenging, frustrating, but ultimately rewarding experience. I’m not sure where I’ll go from here, maybe I’ll try to refine it further, or maybe I’ll move on to some other crazy project. But one thing’s for sure: I’ll never look at a watch the same way again.